MIL-B-16029G

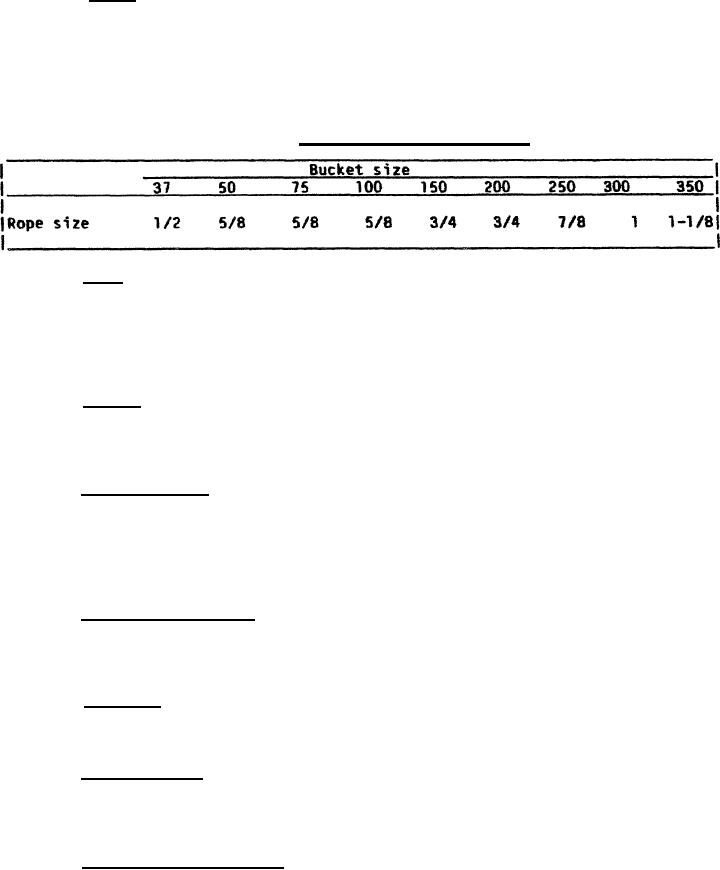

3.6.2 Arch. The front end components shall be of cast or rolled plate

steel construction. The arch shall be designed so that it will withstand its

proportionate share of the load during all operation cycles without

defomation or failure, provided it is not subjected to loading or digging

forces in excess of four times the breaking strength of the size dump rope

specified In table II. Ample clearance shall be provided for the flow

excavated material in and out of the bucket.

TABLE II. Dump rope size (inches).

3.6.3 Lip. The lip shall be cast manganese steel conforming to

MIL-S-17249, cast steel conforming to ASTM A 27 and ASTM A 148, or alloy steel

plate conforming to ASTM Designation A 514, or better. The lip shall form the

cutting edge. The extent of the lip shall conform to the manufacturer's

standard practice, and shall accommodate the teeth as specified (see 3.6.4).

All lips or cutting edges shall enable replacement of expendable components.

3.6.4 Teeth. Unless otherwise specified (see 6.2), manufacturer's

standard bucket teeth shall be furnished. When specified (see 6.2), teeth

shall conform to MIL-T-52176. The teeth shall be readily replaceable by the

use of standard tools.

3.6.5 Hitch plates. The hitch plates for attaching the drag chains to the

bucket shall be of one of the steels specified in 3.6.3 except for types I and

II buckets of size 100 and smaller, the steel may conform to ASTM A 27 and

ASTM A 148. The hitch plates shall provide not less than two positions for

the attachment of the drag chains as an aid in controlling the digging depth.

The plates shall be either riveted or welded to the bucket body.

3.6.6 Trunnion brackets. The trunnion brackets shall be of one of the

steels specified in 3.6.3. The trunnion brackets shall be accurately located

on the bucket body to provide proper balance, and shall be either riveted or

welded in place.

3.6.7 Runners. Renewable runners shall be provide and shall be either

riveted or welded to the heel of the bucket. The runners shall be of one of

the steels specified in 3.6.3.

3.6.8 Heel plates. Renewable or integral cast type heel plates shall be

provided. Renewable heel plates shall be either riveted or welded between the

runner bars at the heel of the bucket. The plates shall be of one of the

steels specified in 3.6.3.

3.6.9 Corner wearing shoes. All buckets shall have renewable cast corner

wearing shoes of the material specified in 3.6.3. Renewable wearing shoes

shall be bolted, riveted, or welded to the bottom corner.

5

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business