MIL-B-16029G

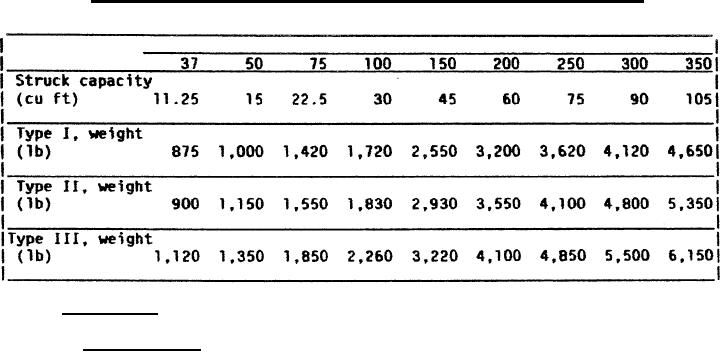

cutting edge, multiplied by the average inside bucket width, which is

determined by measurements of the top and bottom of both the front and rear

reference points of the bucket. The weight of class S buckets, as delivered,

shall be not less than specified for the respective size in table I. In

addition, the delivered weight of class S buckets of size 37 through size

100 shall not exceed the respective specified weight by more than 10 percent,

and the delivered weight of class S buckets of size 150 through size 350 shall

not exceed the respective specified weight by more than 12 percent. The

delivered weight of class P buckets shall be not less than 97 percent of the

weight specified in table I, for the respective size of class S buckets. The

bucket body, including teeth, hitch, plate pines, trunnion pins, and anchor

pins shall be not less than 70 percent of the total weight of the bucket.

TABLE I. Capacitiies and weights (weights based on class S buckets).

3.6 Components.

3.6.1 Bucket body. The bucket body shall include bottom, side, and back

plates, with partial or complete lip and bottom, dependent on manufacturer's

commmercial practice. Method of connecting bucket body assembly of arch, lip

or complete bottom, hoist trunnions, hitch plates, runner bars, heel plates,

and comer wearing shoes shall be either cast integral or welded, or

combination of both. The body shall be designed in accordance with best

commercial practice to handle the class of excavation for which it is

intended. The inside surfaces shall be smooth and free from projections. The

connections between the bottom and side plates shall have a radius and the

back plates shall be curved sufficiently to provide satisfactory loading and

dumping performance. Cast lips or cast bottoms and connections to body and

side plates, shall provide a firm joint that is consistent with industry

practice for weldments or riveted components. Inside clear width at the lip

shall be slightly larger than at the heel to facilitate the discharge of

adhesive material. The plates for the bottom, sides, and back of the bucket

shall be of steel which meets or exceeds the requirements of ASTM designation

A 36. The back and side plates of class P buckets shall be perforated in a

manner that will not impair or weaken the bucket strength.

4

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business